Expert Electronics Prototyping

& Repair Services

Quality assembly and support.

We make it easy.

About SolderTech Solutions

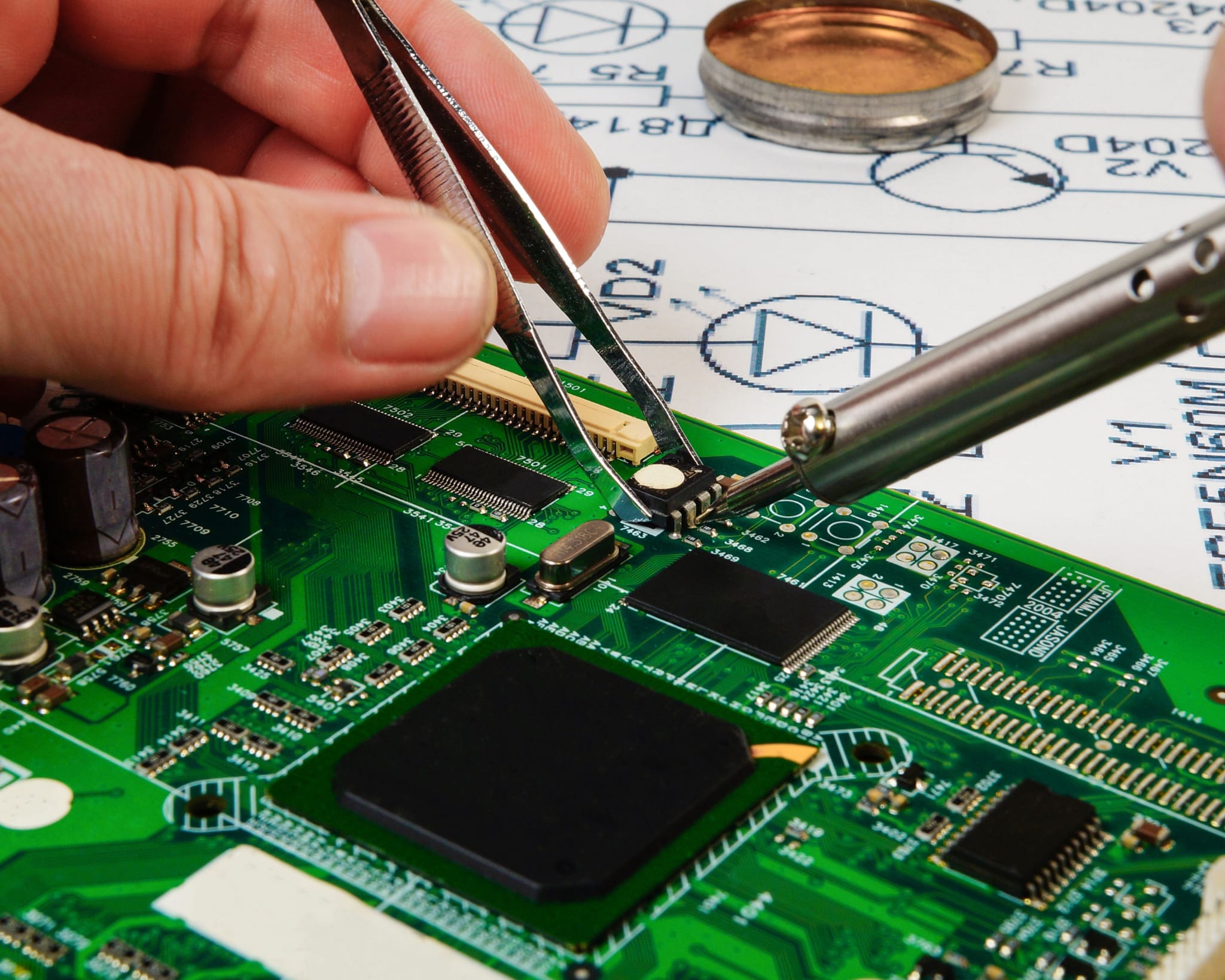

SolderTech Solutions is a dedicated sole proprietorship offering comprehensive

expertise in manual soldering, high-precision assembly, and electronics repair.

Our operations focus on manual prototype soldering, IC rework & repair,

and professional electronic component integration.

With a flexible approach and an individual focus on every project, we serve the

needs of small-to-medium electronics manufacturers, hardware designers, and

private innovators. All services are realized in a specialized ESD-safe

workspace, ensuring reliability and quality in every detail.

Technical Solutions

Hand Soldering

High-precision manual assembly for complex PCBs. We provide full thermal control and surgical accuracy for low-volume production and critical components.

Prototype Assembly

Fast-track hardware development. From 0402 SMD components to complex multi-layer boards, we turn your designs into functional, tested prototypes.

Rework & Repair

IPC-7711/7721 compliant repairs. We specialize in SMD/TH replacement, pad reconstruction, and salvaging expensive production batches.

On-site & Remote

Versatile technical support. We offer direct on-site troubleshooting at your facility or high-level remote diagnostics for immediate hardware aid.

How It Works

Contact & Inquiry

Reach out via form, email, or phone. We discuss your technical requirements and initial project scope to align with your expectations.

Technical Documentation

Send over your Bill of Materials (BOM) and assembly instructions. We analyze the documents to fully understand the hardware complexity.

Detailed Quotation

Based on our analysis, you receive a comprehensive offer including estimated costs and a precise project timeline.

Precision Execution

After approval, we proceed with soldering or repair. You are kept updated on the progress to ensure transparency throughout the build.

Delivery & Support

Final inspection followed by shipping or local collection. We provide ongoing after-sales technical support for every project.

Quality & Standards

IPC Compliance

All soldering, rework, and repair operations follow the strict IPC-A-610 and IPC-7711/7721 guidelines to ensure industrial-grade reliability.

ESD Safe Zone

Our workspace is a fully controlled Electrostatic Protected Area (EPA), preventing damage to sensitive semiconductor components through continuous monitoring.

Quality Control

Every PCB undergoes multilayer visual inspection under high magnification. Functional testing is implemented to guarantee performance before release.

Precision & Focus

A boutique, one-person approach means 100% individual responsibility for every solder joint, ensuring craftsmanship that mass production cannot replicate.

Sectors & Solutions

Frequently Asked Questions

Yes, all services are performed strictly according to the documentation provided by the client. We ensure every technical specification and BOM requirement is followed precisely.

Yes, on-site services are available upon request. Depending on the project, I can travel to your location to provide technical support and perform manual soldering or assembly work on-site.

Turnaround times vary by project complexity. Simple repairs or assemblies are typically finished within 1-2 business days. Larger projects are scheduled individually.

We accept bank transfers (SEPA), card payments, and other standard business payment methods. Specific terms are arranged during the project agreement.

Yes, a professional warranty is provided for all soldering and repair services. We prioritize long-term reliability in every connection.

You can reach out through our contact form, email, or phone. Providing technical files (Gerber, BOM) helps in preparing an accurate quote quickly.

Components are usually provided by the client (BOM). However, for reworks or specific repairs, we can source necessary components through verified distributors.