Advanced PCB Rework and Repair

Restoring high-value industrial and R&D electronics through surgical manual precision and controlled thermal profiling. Engineering support for complex hardware restoration.

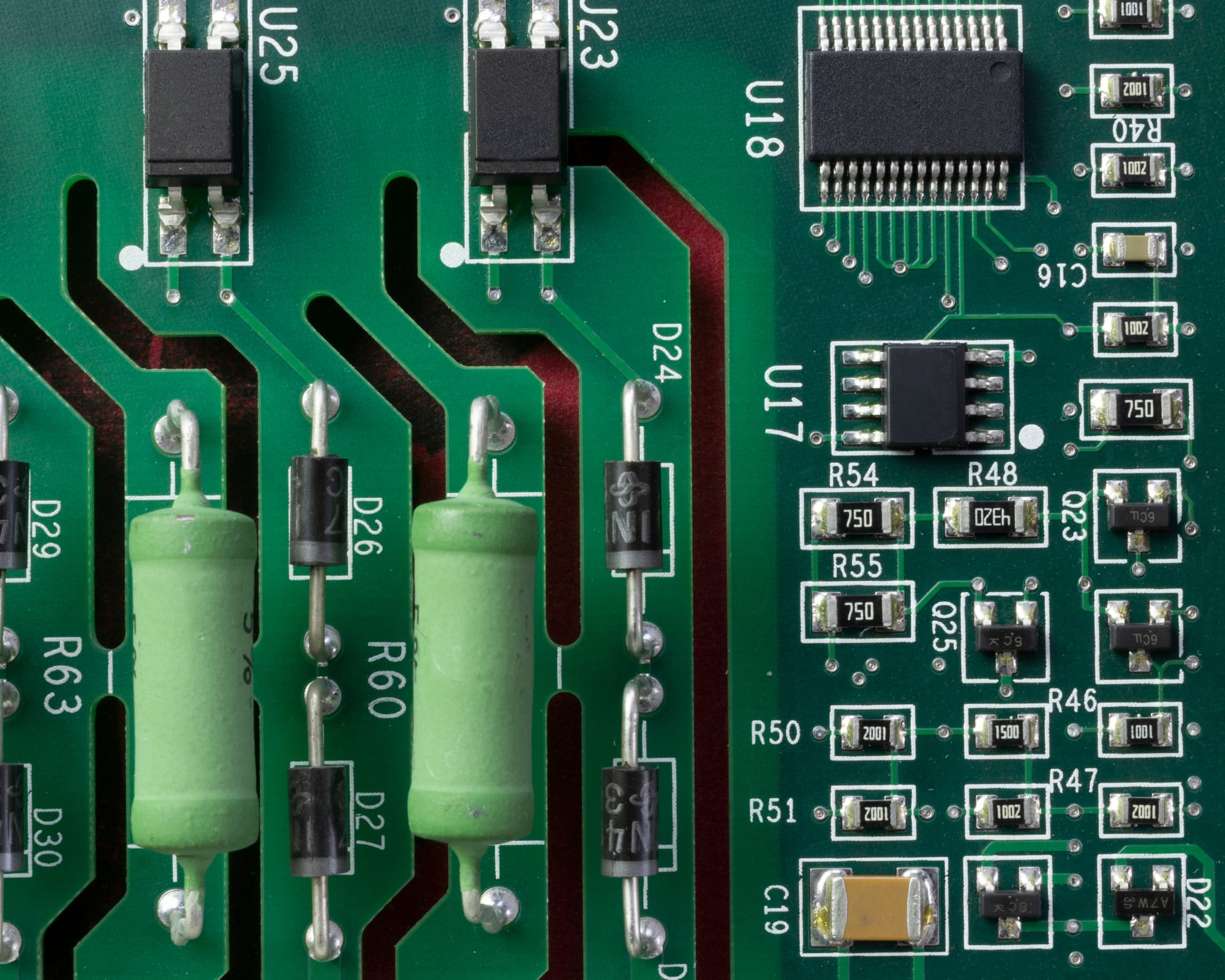

The Science of Circuit Restoration

In the lifecycle of professional electronics, rework and repair is a critical operation that requires a deep understanding of thermodynamics and material science. At SolderTech Solutions, every board is treated as a unique engineering challenge. My approach avoids the risks of excessive localized heating, which often leads to pad cratering, internal delamination, or compromised intermetallic layers.

Whether the goal is component-level replacement or correcting assembly defects, I utilize professional-grade JBC soldering systems and precise hot-air profiling to maintain the structural integrity of the multilayer PCB substrate.

IC Replacement

Precise removal and replacement of high-density SMD packages, including QFN, QFP, and SOIC, utilizing controlled thermal ramp-ups to protect sensitive silicon.

Trace Reconstruction

Microsurgical repair of broken copper traces and restoration of lifted pads using high-bond epoxies and precision jumper wire techniques.

Hardware ECOs

Implementation of Engineering Change Orders (ECO), including manual circuit modifications, "dead-bug" component mounting, and bridge-wire updates.

Failure Analysis

Thorough visual inspection of solder joints and PCB structures to identify cold joints, dendritic growth, or thermal stress damage.

Controlled Thermal Profiling

Effective rework and repair on multilayer industrial PCBs demands a sophisticated thermal strategy. Standard desoldering techniques often apply heat too rapidly, risking damage to internal planes.

My workflow incorporates a multi-zone heating approach. By gradually increasing the board's ambient temperature, I reduce the delta-T between the soldering iron and the PCB. This minimizes mechanical stress on the fiberglass substrate and ensures that the restoration is permanent and electrically sound, following IPC-7711/7721 guidelines.

Precision Pad Restoration

When a component is improperly removed or physically stressed, pads can tear away from the substrate. In high-value hardware, this shouldn't mean the end of the board's life.

I specialize in pad reconstruction under high-magnification optics. By re-establishing the mechanical bond with the board's surface and ensuring a low-resistance electrical connection, I can restore even severely damaged hardware to a state that is often indistinguishable from the original assembly in terms of reliability.

"Precision rework is the ultimate test of an engineer's manual skill. It is about understanding where the heat goes, how the solder flows, and ensuring the device returns to service without a single technical compromise."

Direct Accountability

Many repair facilities operate on a volume-first basis, often neglecting the technical nuances of delicate R&D or industrial hardware. As a sole specialist, SolderTech Solutions offers a different model: direct engineering accountability.

When you commission rework and repair services here, you are dealing directly with the specialist executing the work. This eliminates communication gaps and ensures that failure symptoms or design requirements are fully understood before any heat is applied. This personal oversight is essential for mission-critical hardware where failure is not an option.

Does your hardware require restoration?

Provide the technical details and failure symptoms. Every rework and repair inquiry receives a thorough expert assessment before we begin.

REQUEST TECHNICAL QUOTE